Materials

Polyurethane Foams are the most widely used foams for packaging applications. They are open cell in structure, hence flexible in their handling characteristics and available in a wide range of densities, colours, antistatic and hardness properties. The primary polyurethane foams are ‘polyether’, additional properties and a greater degree of inertness is obtained with the ‘polyester’ variant.

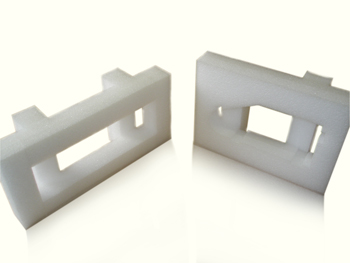

Polyethylene (non cross linked foams) e.g. Jiffy, Stratocell, Ethafoam are closed cell in structure providing good shock absorbing and recovery properties. They are widely used as a cushioning material for heavy products. These materials can be routed and are available in a range of densities and colours including antistatic pink.

Click to enlarge

Polyethylene (cross linked) e.g. Plastazotes, have extremely high strength and durability for their density. Their manufacturing process uses pure nitrogen for foam expansion providing purity and properties which are employed for long term storage of valuable artworks and artefacts. Their fine surface and range of colours make them ideal for presentation packs.

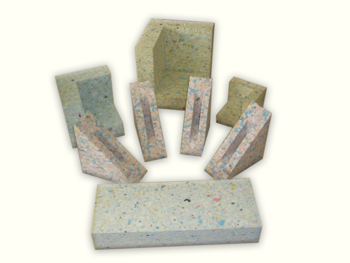

Chipfoams are produced from recycled polyurethane materials in a range of densities from 4lb to 12lb /cu.ft. They have high cushioning characteristics and are frequently used to protect high density products.

Click to enlarge

Composite packs combine the cushion and location properties of foam inner packaging with the rigidity and strength of an outer container to provide a complete pack for transit.

Click to enlarge

Selecting the correct combination of inner and outer packaging components not only ensures safe distribution, but also cost effective materials usage.